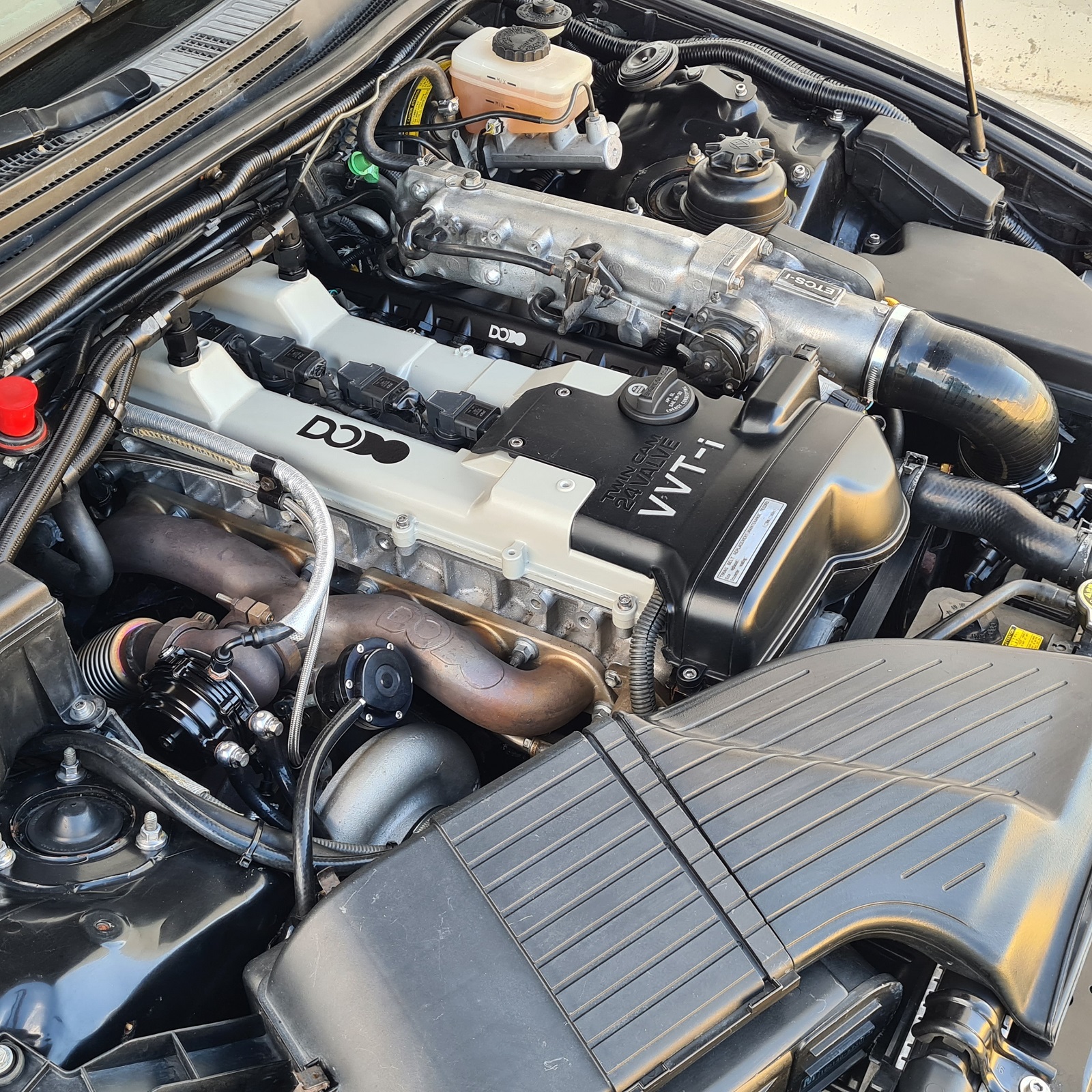

HOW IT WORKS

The QSV is added between your exhaust manifold and your Twin-Scroll-turbocharger. At lower RPMs the flap is closed, blocking one of the turbochargers scrolls. All exhaust gases are forced into the remaining scroll. This results in doubled exhaust speed which lets your turbocharger spool up more quickly (500-1000RPM). This means huge power increases at low-mid RPM and better throttle response! Once you have reached your desired boost pressure, the flap opens and enables the second scroll giving you maximum flow for high power.

SUPERIOR DESIGN & QUALITY

This system is proven to work for many years. We have brought it to perfection for you!

Our QSV is precisely CNC machined out of high grade 316 Stainless Steel. It includes a servicable, billet aluminium actuator.

The actuator can be mounted in 16 different positions in order to eliminate any fitment issues.

PICK THE RIGHT SCROLL

The scrolls of Twin-Scroll-Turbochargers are sized differently. There is one big high-capacity-scroll directing exhaust gases to the outer edge of the rurbine and one smaller high-velocity-scroll directing exhaust gases to the inner inner edge of the turbine for improved spool. For best results, you want to install the flap to the big scroll which is located closer to the compressor side. This way, all the exhaust gases have to go through the high velocity scroll improving spool even more.

Our design makes sure you can always pick the right scroll without having any fitment problems!

CONTROL

Our QSV comes with a 1bar / 14psi spring. To control the openeing pressure you have to add a control solenoid which you can either control with your standalone ECU or a hobbs switch.

NOTE

When adding the QSV to an existing setup, have in mind the thickness of the QSV (20mm – 3/4″). You may have to modify the downpipe.

The QSV is designed for use with a Twin-Scroll-turbocharger and a non-divided manifold. But if you already have a Twin-Scroll-manifold you can keep it. The lowered center divider of our QSV enables exhaust gases to be redirected from the closed scroll to the open scroll. However, for further improved flow between the scrolls, we recommend either adding a non divided spacer or grinding down the divider of your manifold as deep as possible.

| Weight | 2 kg |

|---|---|

| Dimensions | 20 × 20 × 7.5 cm |

| Flange Type | T4 |

| Material | SS316 |

| Machining | billet CNC |

| Origin | made in China |